HOW TO SIZE A PUMP

Water Booster Pumps are essential for maintaining proper water pressure in your home or commercial building. Whether you're upgrading an existing system or installing a new one, understanding how to size a water booster pump is crucial to ensure optimal performance. In this guide, we will explain the process of sizing a water booster pump and provide a glossary of terms commonly used within the industry.

WHAT IS A BOOSTER PUMP?

A water booster pump is a device designed to increase water pressure in a building's plumbing system. Its primary purpose is to ensure a steady flow of water at adequate pressure, especially during periods of high demand or when the natural water pressure is insufficient.

They work by utilising an electric motor to drive an impeller or a set of impellers. As water enters the pump, the impeller spins, creating centrifugal force that enhances the pressure and propels the water forward. This increases pressure allows the water to overcome any resistance or friction in the pipes, providing a consistent and reliable water supply at the desired pressure levels.

BENEFITS OF A WATER BOOSTER PUMP

Water booster pumps or water pressure booster pump's main advantage is to increase the ability to boost water pressure, ensuring adequate flow and pressure for showers, sinks, toilets and other water dependant appliances and fixtures.

During peak usage times, such as when multiple showers are running simultaneously or when there is high demand for water in a commercial building, the natural water pressure may drop. A water booster pump ensures a steady and uninterrupted supply of water, maintaining optimal pressure levels throughout the building.

In some cases, low water pressure may lead to inefficient water usage, as individuals compensate by keeping taps open for longer periods or using more water to achieve desired results. By boosting water pressure, a water booster pump can help improve water efficiency.

SIZING A WATER BOOSTER PUMP

Sizing a water booster pump is an important step in ensuring that your water system operates efficiently and meets your specific needs, It involves determining the flow rate and pressure requirements of your water system. Below are some of the question you may get asked, or you can ask yourself, so you can begin to understand what size system is required.

- How many baths are in the property?

- How many showers are in the property?

- How many wash basins are in the property (bathroom sinks)?

- How many toilets are in the property?

- How many sinks are in the property?

- How many washing machines are in the property?

- How many dishwashers are in the property?

- How many outside taps are in the property?

In addition to the above, we will also need to know how many floors are in the property, as you will need to deliver water to the highest floor at an ideal pressure. Generally, this is 2 bar. However, as the water travels through the pipework to the outlet, you will see a reduction in pressure due to pipe losses. It is good practice to factor this into your calculation when sizing a booster set.

If this something which you are unsure of, we have experience staff who can guide you through this process and help let you know what size pump you will need. For more information, please contact us

HOW TO READ A PUMP CURVE GRAPH

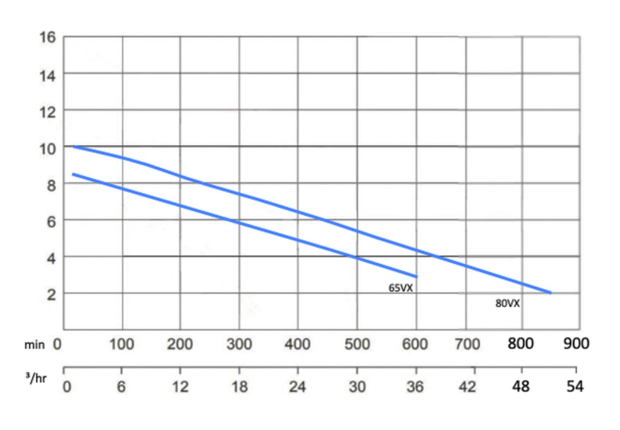

Above image Displays flow and pressure

Flow (x) axis - how much water the pump can move

Pressure (y) axis - also known as head, measures in feet or meters

The Mid curve is best efficiency point for any pump, either end is the maximum the pump can work at (which if kept constant the pump would burn out) and the minimum the pump can work at.

When reading a booster pump curve, it involves understanding the information presented on the curve and using it to determine the performance characteristics of the pump. Here's how you can read a booster pump curve:

1. Axis Labels: The pump curve will have 2 main axis - the vertical axis (y-axis) and the horizontal axis (x-axis). The y-axis typically represents the pump's head (pressure) in units such as meters of feet, while the x-axis represents the pump's flow rate in units such as gallons per minute (GPM) or litres per second (L/S)

2. Performance Curve: The pump curve is a graphical representation of the pump's performance. It shows how the pump's head (pressure) varies with respect to the flow rate. The curve is typically a line or a series of data points that connect the points of operation for the pump/

3. Operating Points: The pump curve will have one or more operating points marked on it. These points represent the flow rate and head (pressure) at which the pump operates under specific conditions. The operating points are determined by the system requirements and the pump's performance capabilities.

4. Efficiency and Power: Some pump curves may also include additional information such as efficiency and power consumption. Efficiency represents the ration of the pump's hydraulic power output to the input power and is usually shown as a percentage. power consumption refers to the amount of electrical power required to operate the pump.

5. Interpretation: To read the pump curve, locate the operating point or desired flow rate on the x-axis and follow it vertically unit intersects with the pump curve. Then, read the corresponding head (pressure) value on the y-axis. This will give you an indication of the pump's performance at that particular flow rate.

It's important to note that pump curves are specific to each pump model and are provided by the manufacture. They are used to select the appropriate pump for a given application and to understand its performance capabilities under different operating conditions.

By understanding how to read a booster pump curve, you can make informed decisions about pump selection, system design, and troubleshoot in order to meet the desired flow rate and pressure requirements.

Single Booster Tanks

Twin Booster Pumps

Booster Pump & Tank Sets

Cat 5 Booster Pump Sets

Glossary

FLOW RATE

Also known as volumetric flow rate, is a measure of the amount of fluid (liquid or gas) that passes through a given point in a specified period of time. It is typically expressed as the volume of fluid that flows per unit of time, such as litres per second or cubic meters per hour. Flow rate is influenced by factors such as the diameter of the pipe or channel through which the fluid is flowing, the pressure difference across the system, and the viscosity of the fluid.

FRICTION LOSS

Friction loss refers to the pressure drop or energy loss that occurs due to the friction between the fluid and the walls of a pipe or conduit. It is a common term used in fluid mechanics and is particularly relevant in the design and analysis of piping systems. Friction loss is influenced by factors such as the diameter and length of the pipe, the viscosity of the fluid, and the flow rate. It is typically expressed in units of pressure, such as pounds per square inch (psi) or pascals (Pa) and is an important consideration in determining the efficiency and performance of fluid flow systems.

MAX HEAD

The term 'Max Head' refers to the maximum height or pressure that a pump can generate and maintain against gravity (when pumped straight up). It is a measure of the pump's ability to lift or push fluid to a certain height. The max head is typically expressed in units of length, such as meters or feet, and is an important specification when selecting a pump for highest point to which the pump can deliver fluid and is influenced by factors such as the pump's horsepower, impeller design, and system resistance. Understanding the max head is crucial in ensuring the pump can meet the required pressure or height requirements of a specific system or process.

PRESSURE TANK

A pressure tank, also known as a pressure vessel, is a container used to store and regulate the pressure of a fluid or gas. It is designed to withstand high pressure and is commonly used in various industries and applications. Pressure tanks are typically made of sturdy materials such as steel and are equipped with pressure relief vales for safety purposes.

The main purpose of a pressure tank is to maintain a constant pressure in a system by storing excess fluid or gas when the demand is low and releasing it when the demand is high. This helps to reduce the cycling of pumps or compressors and ensures a steady flow of fluid or gas, Pressure tanks are commonly used in water supply systems, hydraulic systems, pneumatic systems, and many other industrial processes.

In addition to regulating pressure, pressure tanks can also serve as a reservoir for emergency backup supply, provide surge control, and help prevent water hammer effects in plumbing systems. They come in various sizes and designs to accommodate different pressure and volume requirements.

LOADS

Refers to the amount of work or pressure that the pump needs to generate in order to overcome the resistance in a fluid system and deliver the desired flow rate.

Booster pumps are commonly used to increase the pressure of water or other fluids in a system, such as in buildings or industrial application, where there may be a need for higher water pressure. The loads in this case refer to the pressure requirements of the system.

The loads on a booster pump can vary depending on the specific application and requirements. factors that determine the load include the desired flow rate, the distance the fluid needs to be pumped, the elevation or height the fluid needs to be lifted, and any friction or resistance in the piping system.

Summary

To properly size and select a booster pump, it is importance to consider the loads or pressure requirements of the system. This involves calculating the total head or pressure that the pump needs to generate to overcome the resistance and deliver the desired flow rate. It also involves considering factors such as the system's peak demand, any pressure losses due to friction, and any additional pressure requirements for specific equipment or fixtures.

How To Size a Breaker Tank?

Cold Water Storage Tank Regulations

Login

Login